Custom-Fit Earplugs Using Phone Scanning Technology

For six months, I worked on an exciting project with a teammate, developing an innovative solution to make custom-fit earplugs more accessible through phone scanning technology.

Hearing damage is irreversible—unlike a broken leg, your ears cannot heal once damaged. In the Netherlands alone, 300,000 people suffer from permanent tinnitus (Amsterdam UMC, 2019). The best way to prevent hearing loss is by using custom-fit earplugs, but these typically cost at least €130, making them unaffordable for many. We believed this price was too high and set out to develop a more affordable alternative using 3D phone scanning technology.

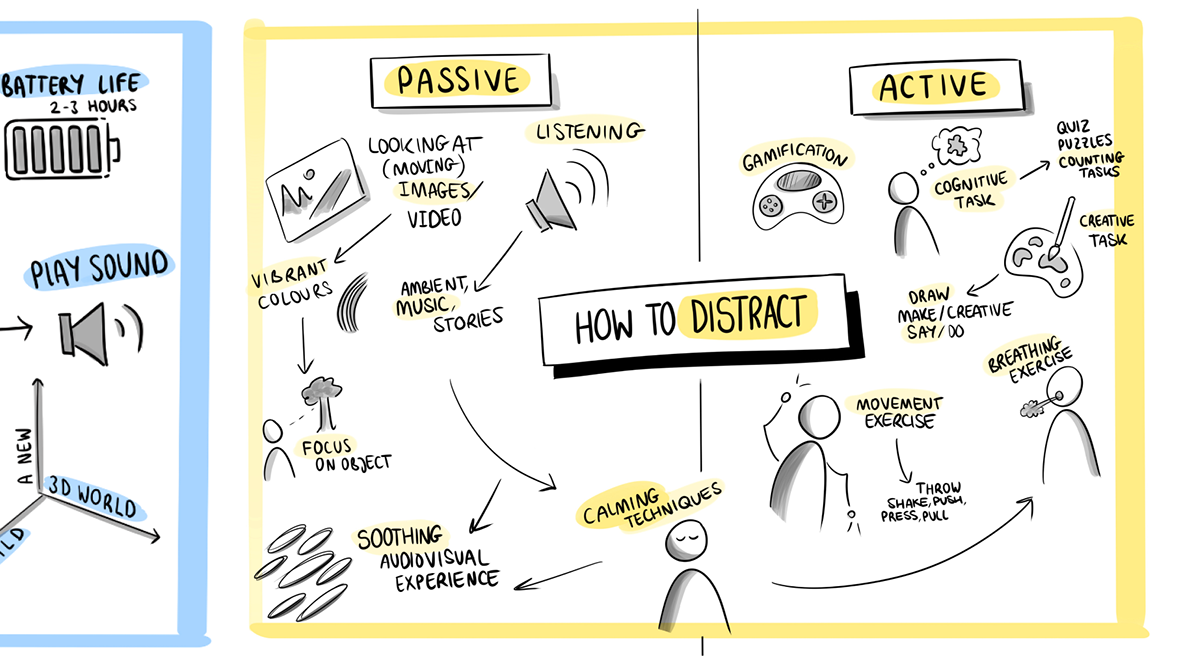

We started with a simple yet powerful idea: creating custom-fit earplugs using a smartphone camera and photogrammetry. To bring this concept to life, we prototyped using 3D printing, developing precise molds that we filled with skin-friendly silicone to produce earplugs that fit perfectly.

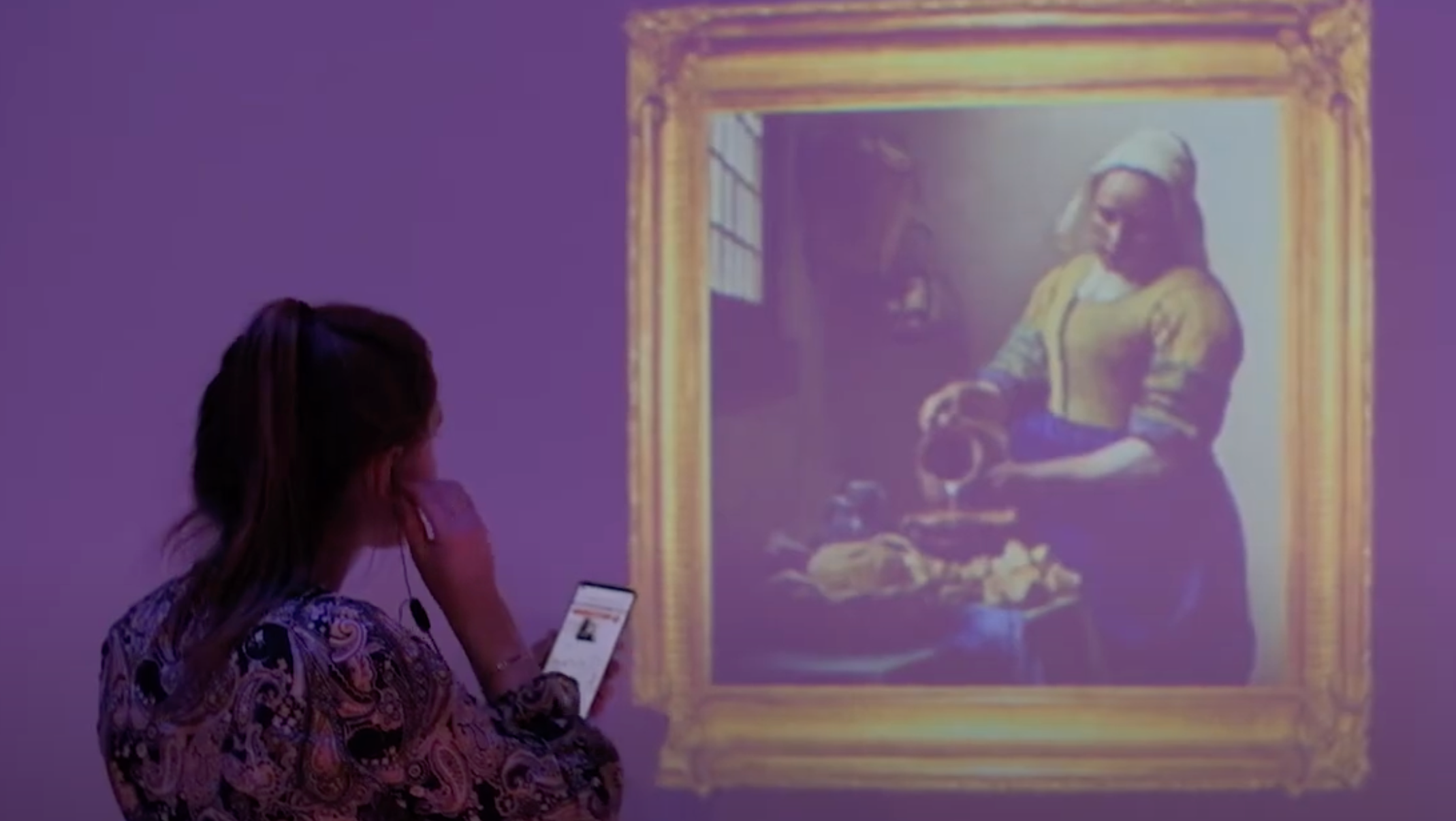

Scanning the ear

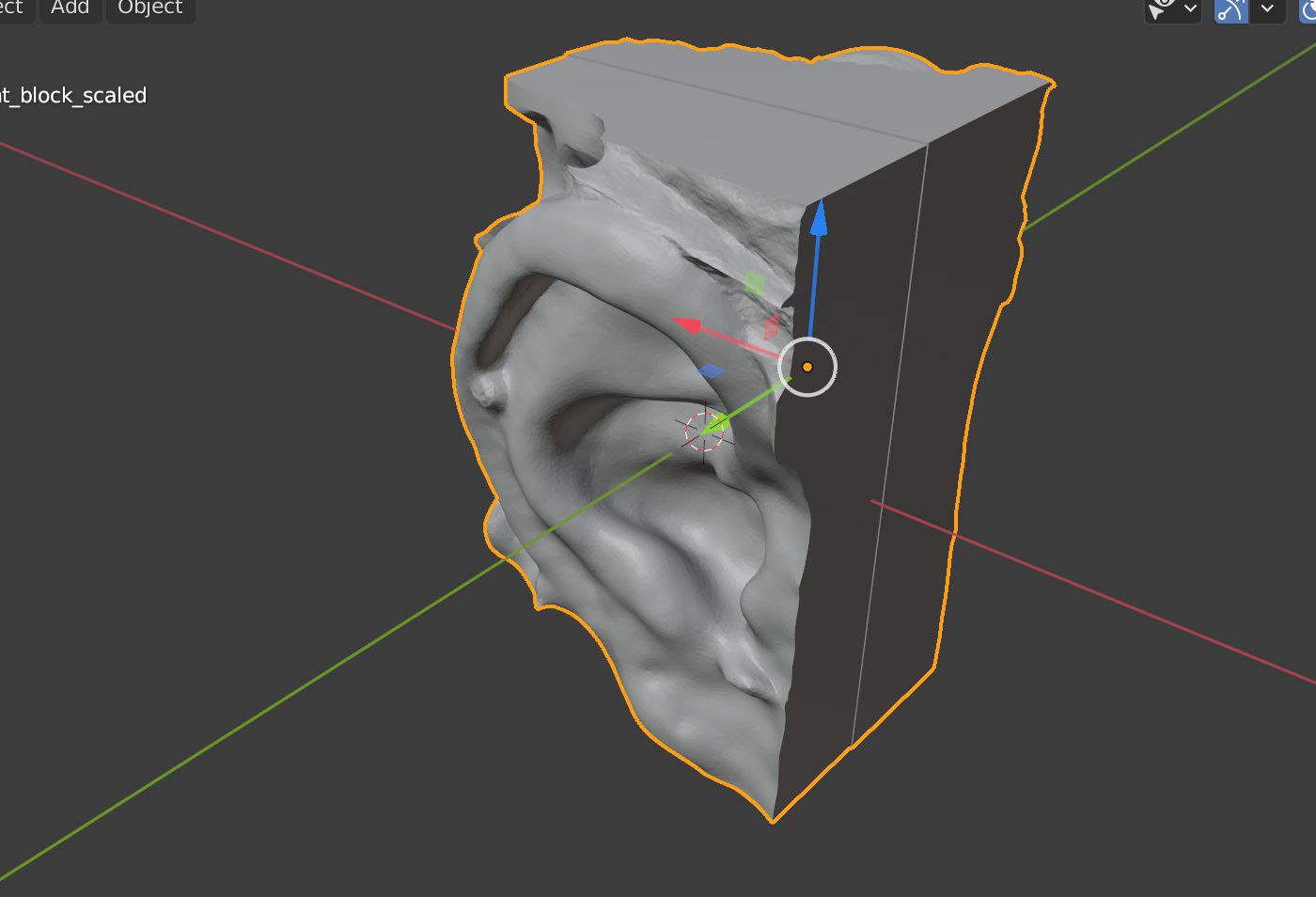

Converting the scan to 3D models for 3D printing

Prototyping

Prototype testing: Proof of concept

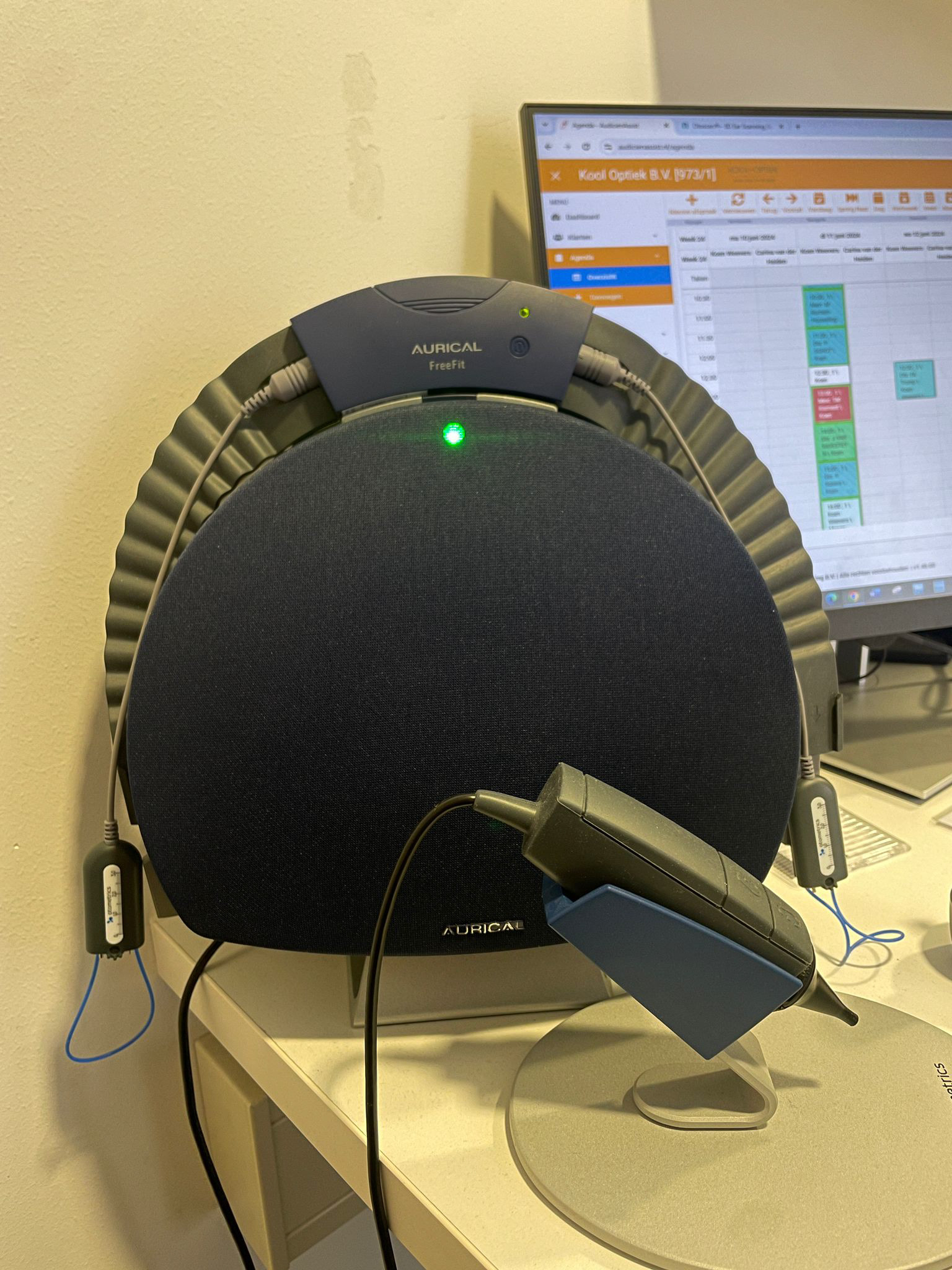

To validate our proof of concept, we consulted an audiologist (ear specialist) and performed a leakage test to measure the sound damping effect. The results showed a reduction of -18dB, proving that our earplugs provided effective hearing protection.

Winning a pitching prize!

Our work culminated in a pitch at STUD Dragon’s Den, where we won a €1000 prize for our innovative approach. This project demonstrated the potential of smartphone-based 3D scanning to revolutionize the custom-fit earplug industry, making high-quality hearing protection more affordable and accessible for everyone.